Various Applications

Helium Leak Detection services performed for the following applications

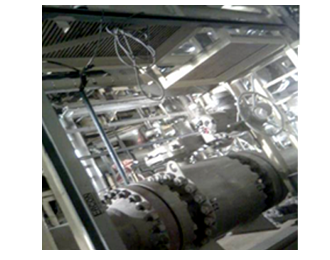

Pipeline/Heat Exchanger Inspection

We also offer service of testing of minute leaks using Helium gas for equipments like Columns, Reactors, Exchanger, Vessels, Pipelines and Oil Platforms by positive pressure method. Typically, in these cases, we pressurize the equipment / pipeline with Nitrogen / Helium in the ratio of 90:10 to the testing pressure required by the client and check for leaks in all probable areas. Even minute leaks can be identified using our Sensitive Helium Spectrometer. We use specially designed booster pumps for high pressure testing application

We have undertaken such jobs for two new offshore platforms top sides, a flare platform and an interconnecting Bridge for L & T Ltd. INDIA.

--------------------------------------

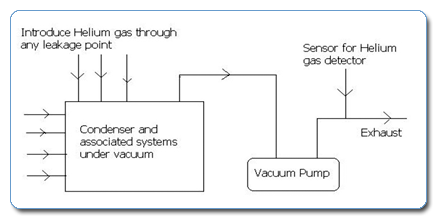

Condenser Tube Leak Identification

This will be done, when the unit is in partial isolation or full shut-down provided vaccum pump should run and to arrange steam passing

--------------------------------------

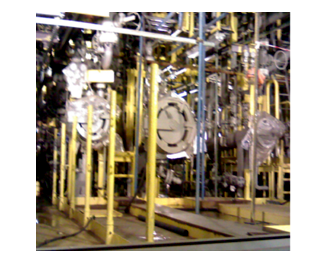

Critical Valve Leak Testing

We do critical valve leak testing inspection by Helium Leak Testing

--------------------------------------

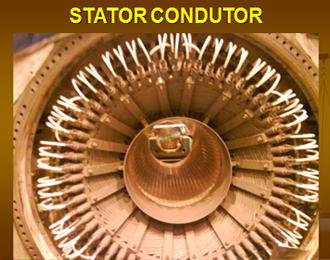

Hydrogen Cooled Generator Leak Inspection

In thermal power plants , we carry out Hydrogen cooled generator leak identification either unit is offline/ online, we will also undertake stator conductor inspection when the unit is offline. Our Engineers are well trained in carrying out the test and to interpret the results accurately. The job will be carried out by ASNT Level II Certified Engineers.

--------------------------------------

On Shore

Power Plant & Refineries

Hydro Carbon Lines