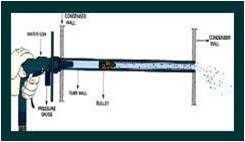

SURFACE CONDENSER TUBE CLEANING SERVICE USING SPECIALLY DESIGNED BULLETS / SCRAPERS POWERED BY WATER PRESSURE

"BulletCleaning": Cooling water sources cause different tube fouling problems,affecting the heat transfer and life expectancy of Condensers and HeatExchangers.PowerStations, Refineries, Petrochemical and other industries in various countries employ"BulletCleaning"as an effective and efficient method to clean the condenser tubes. We offer this Tube Cleaning Service using this unique Bullet Shot method which is the fastest,most economical,safe & environmentally friendly procedure.

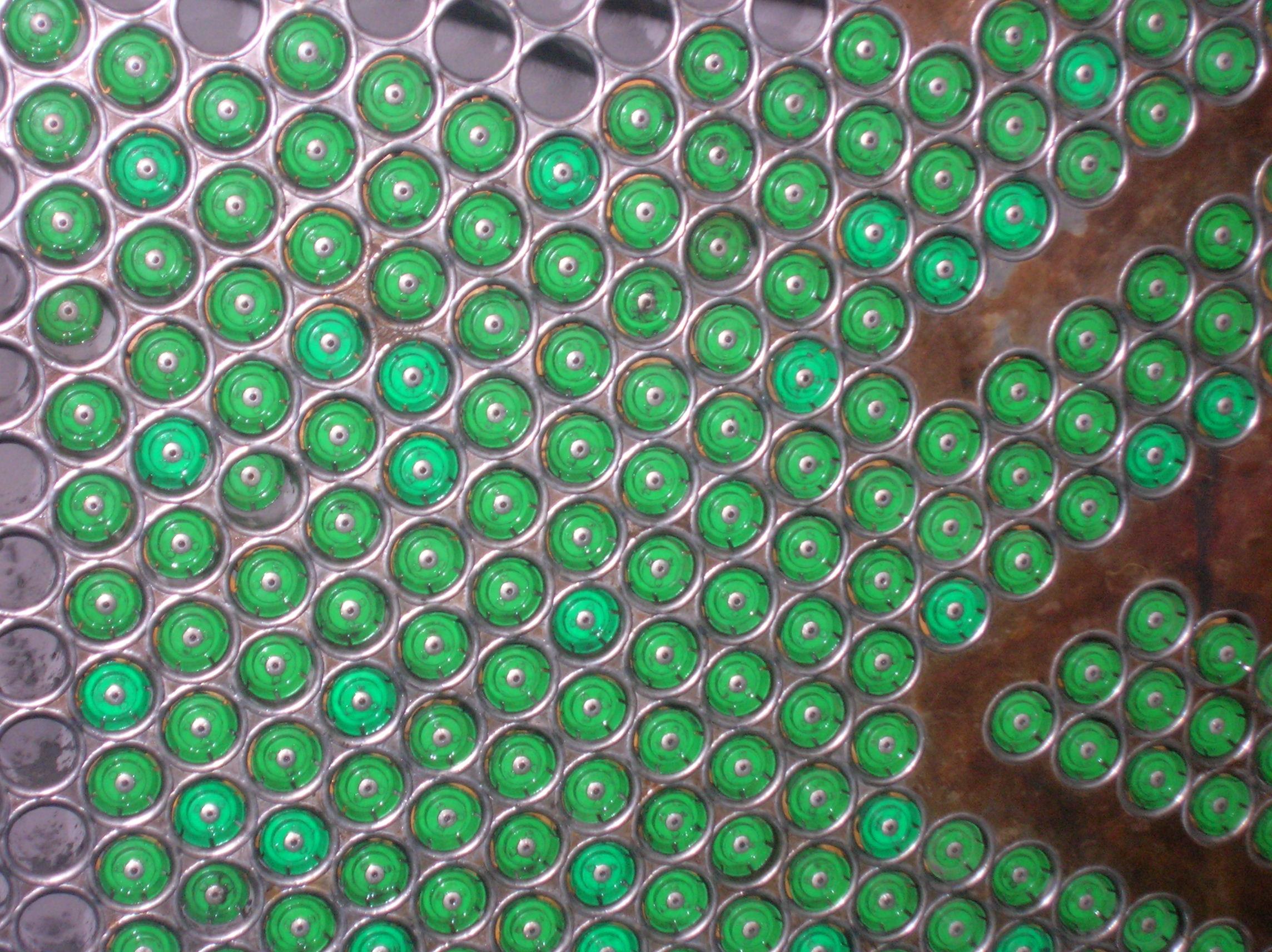

Technique : Spring loaded tube cleaners (Bullets) are shot through fouled Condenser Tubes using specially designed water guns at 10-15 Kg/cm2 pressure. The bullets moving through the tube from one end to the other in a linear motion scrape off the deposits and corrosion scales. Water from the gun flushes out the scraped deposits resulting in a clean inside surface for the tube, ideal for good heat transfer. Tube cleaners, which exit at the other end of the condenser, are collected, cleaned and used again.

Adavantages This is one of the quickest ways to clean the condenser tubes with the following benefits:

- Big cost saving

- Very limited ShutDown Time

- No damage to tube – hence longer tube life

- Improved plant availability & efficiency

- Low consumption of power & water

- No Environmental pollution

we are extremely well equipped with equipments and we will address/attend your emergency cleaning schedule within a very short duration. You can plan your short schedule and inform us and we will keep our resources ready at your location and once the unit goes for shutdown, immediately we can start the job and complete the job quickly. We have done bullet cleaning services in many countries in Asian and African continents successfuly.

SHELL SIDE CLEANING

We offer shell side cleaning of surface condenser tubes with non ionic bio-degradable surfactant solution to enhance the performance of the system. The cleaning approach will help to remove scales from outside of the condenser tube and hence heat transfer will get improved.

We have mastered this cleaning technique over the last sixteen years and so far cleaned 15 million tubes successfully. Today we execute simultaneously Seven to Eight sites all across the world.

We will also carry out condenser tube cleaning by bullet shot method service during partial isolation basis(i.e.) one part of the condenser is to be given for cleaning and another part should be in running condition and vice versa..