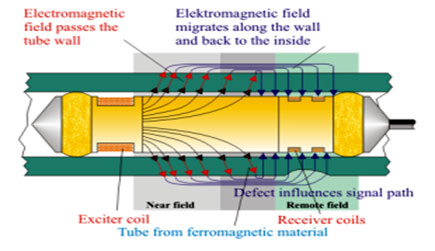

RFET - REMOTE FIELD EDDY CURRENT TECHNIQUES

Remote Field Eddy Current Technique(RFET) . is based on the transmission of an electrromagnetic field through the tube material.The exciter coil generates eddy currents at low frequency in the circumferential direction.The Electromagnetic field transmits through the thickness and travels on the outer diamter.A receiver coil that is placed in the remote field zone of the exciter picks up this field.In this Zone,the wall current source dominates the primary field directly from the exciter.The RFET is generally used for detection of wall loss in Carbon Steel Tubes.

ECT Inspection will be done by experienced LEVEL II Certified NDT Engineers as per ASTM requirements and service report will be given with color code mapping

Advantges

- Detection of wall loss

- Ideal for ferrous tubes

- RFT can detect defects away from tube support plate and tube sheet

- Detect localised corrosion/erosion

- Inspect ferromagnetic materials (carbon steel and stainless steel)

Pulsed Eddy Current Testing ( PECT) :

We carry out PECT of the sphere legs to determine any prescence corrosion under fire proofing (or) insulation, where appropriate technique incorporate a PEC probe whcih will scan the circumfrence of the sphere legs , data shall be recorded and saved for later analaysis.

LFET

LFET Scanner is used to detect material loss which caused by corrosion or other detoriation process.The LFET operated scanner moves over the entire surface of the tank,while generating an electromagentic field into the steel plate.The Electromagnetic field generates Eddy current in the conductuive material.The system measures the changes in the electromagnetic Field caused by the generated eddy current. The defects and the corrosion maps are calculated from these collected values. LFET scanners are used widely to detect corrosion pits, Holes, Material loss caused by corrosion on storage Tank, Tank bottoms etc.,

LFET for Boiler Tube Testing and tank floor inspection.It also helps to identify potential boiler tube failures and replace the sections during an outage.

Advantages:

- Identification of Caustic and Phosphate Gouging.

- Corrosion Cells

- Hydrogen Damage

- Oxygen Pitting

- Cracking,Erosion and Manufacturing Defects.